Welding & Inspection

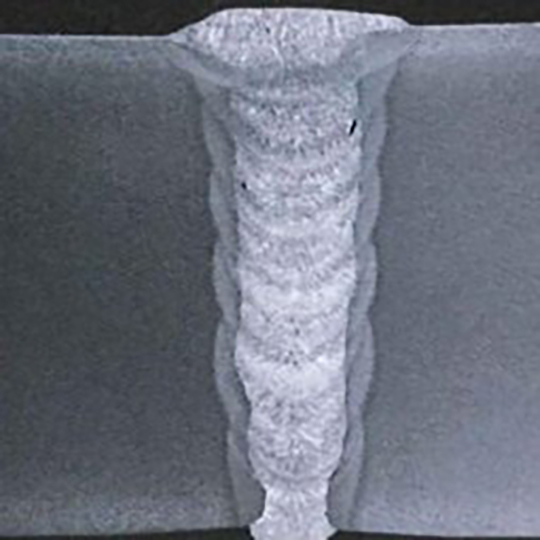

Welding is the primary technique used in the fabrication of pipelines and as such research is performed in a number of areas to assess the properties (i.e. corrosion, mechanical) of the material, including the girth and longitudinal welds, and how they are affected by different pipeline installation methods. This area of research includes assessment of full and small scale testing techniques, comparison of different tests and techniques, including validation by FEA modelling.

The inspection of the pipe material using Non-Destructive Techniques (NDT), which includes AUT, RT and other manual techniques within the pipe mill and during pipeline fabrication, is an important step to verify the integrity of the pipeline. Therefore research is performed to assess the capability of current and potential NDT techniques, methods for the use of ILI data to enhance the effectiveness of modelling techniques, and the impact of weld defects considering their orientation and morphology.